How to Choose the Best Packaging Flute to Protect Your Product

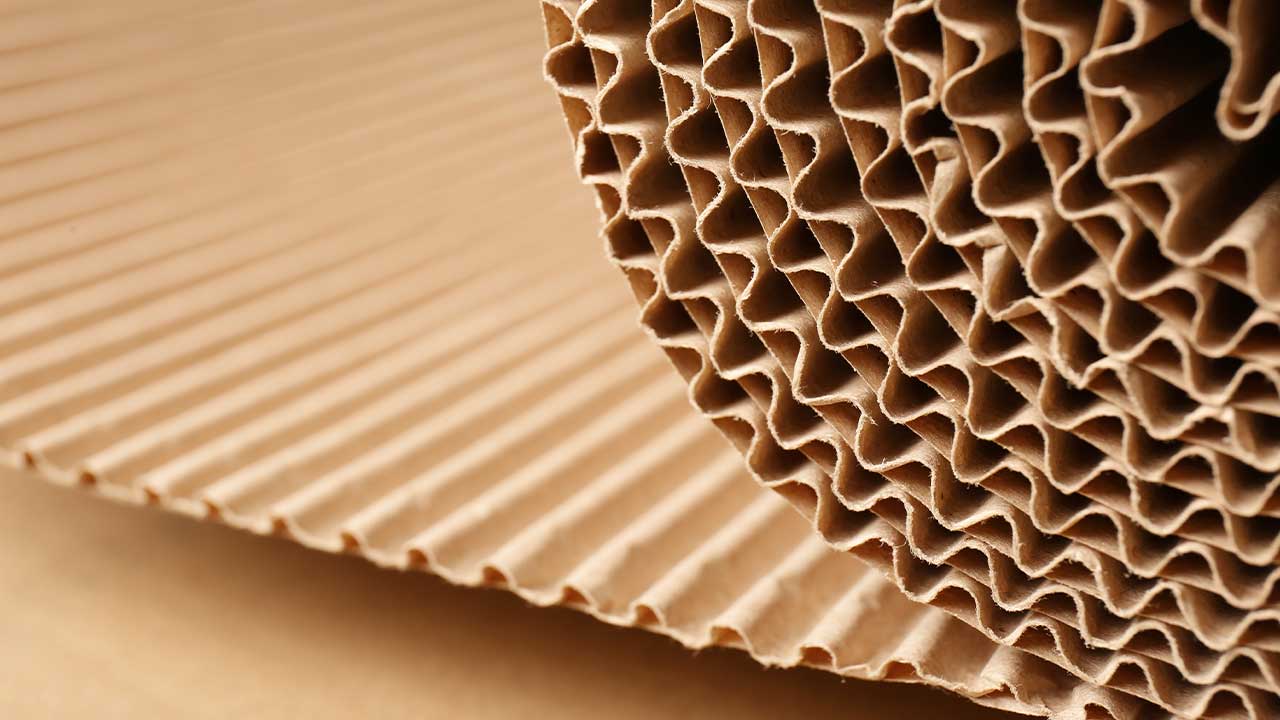

One of the most crucial aspects of logistics is the packaging of goods. Packaging materials provide much-needed security for the items stored inside, and carton boxes are among the most popular packaging materials. The strength of these carton boxes is based on the flute.

Flute refers to the material contained between liner boards of the carton box. The construction of the flute helps to make the carton more durable and able to withstand more pressure. It affects how easily the box dents and the height the boxes can be stacked for shipping.

How thick is flute corrugated?

The thickness of the flute is essential in determining how sturdy the carton box or shipping container will be. Most flutes found in the packaging of products made by a standard flute lamination machine is around 0.25 mm in thickness.

This thickness can vary depending on the product being packaged and the specific requirements of the client. However, most clients will want to buy ready-made packaging materials, and most ready-made packaging utilizes a standard flute lamination machine.

What is the difference between E-flute and B-flute?

- The major difference between the E-flute and B-flute is the number of flutes per square meter. This number determines the strength of the box and its printability. While generally, E-flutes have more flutes per square meter, they are thinner in size. This gives them more storage space at the expense of strength. These types of flutes fold easily and can become distorted quickly. Additionally, they are the best to print on, as their size allows them to roll through printers easily.

- B-flute packaging is more suited to carrying heavier products or goods. These type of cartons contain fewer flutes per square meter, but the largest arch size, which adds to their strength at the expense of space. The thickness of the flute limits the space in the cartons; B-flutes are twice the thickness of E-flutes. B-flutes are also less suited to printing. All that matters when it comes to them is capacity and strength.

What is the strongest type of cardboard?

The strongest type of cardboard happens to be corrugated cardboard. Its strength is owed to the fact that it contains larger flutes. These larger flutes contribute to making the corrugated cardboard boxes sturdier and allow them to stack higher without bending. For the most durable type of cardboard, corrugated cardboard is the go-to option.

What is take up factor in corrugated cardboard?

Take up refers to the pressure that a corrugated box can withstand with other similar boxes stacked on top of it. It is directly related to the material used in making the corrugated box, the number of flutes, and their size. Boxes with B-flute are known to have a better take up ratio compared to boxes made with E-flute.

Final Thoughts

Logistics without proper packaging is a futile endeavour. It is crucial that you factor in matters such as the flute to facilitate good logistics.